Topic: Internet

The new Firefox 1.5 web browser is available. It is a great browser I have been using for at least a year. It is free, secure and has great features.

You can also try a search "roll" I have setup for the various curiouscat.com sites (via Rollyo). This allows you to search those sites I have included in the "roll" and only those sites.

I have also setup a management "roll" which includes some of my favorite management sites. This is a great tool that lets you search a predefined list of sites (including blogs). You can also setup your own "rolls." I think this is a very nice feature, let me know what you think.

You can add these search rolls to your Firefox search box (so you can select to search using Google, Yahoo... or one of these search rolls).

Also, if you have not looked at Open Office yet, take a look at it also (previous post: OpenOffice 2.0). We also have a page with some of the freeware we think is worthwhile.

This now serves as a blog to collect some of the comments I make on other blogs related to management improvement (Deming, lean thinking, six sigma, leadership, systems thinking, respect for people...). Read my main management blog: Curious Cat Management Improvement Blog

Tuesday, November 29, 2005

Monday, November 28, 2005

Toyota Chairman Comments on India and Thailand

Topic: Management Improvement

Toyota Chief Comments on India, Thai Cos.

While this might be a bit of an exaggeration part of what keeps Toyota improving is that they do not rest on their past success. They are continually looking to improve.

More news on Okuda Hiroshi's visit to India, Japan sees India shining

Related Posts:

Toyota Chief Comments on India, Thai Cos.

The chairman of Toyota Motor Corp. said Monday that auto companies in India and Thailand may soon overtake those in Japan because of their increasing focus on quality.

While this might be a bit of an exaggeration part of what keeps Toyota improving is that they do not rest on their past success. They are continually looking to improve.

He said no Japanese firm has won the Deming prize in recent years as they are not showing interest in winning this coveted prize, whereas Indian companies such as motorcycle and scooter maker, TVS Motor Co. and Rane TRW Steering Systems Ltd. have won the Deming prize.

More news on Okuda Hiroshi's visit to India, Japan sees India shining

Toyota Motor Corporation chairman Okuda Hiroshi, who heads Japanese trade body Nippon Keidanren, will lead a high-powered mission to India from November 27-30.

The delegation is likely to meet Prime Minister Manmohan Singh, finance minister P Chidambaram and commerce minister Kamal Nath.

The delegation is likely to meet Prime Minister Manmohan Singh, finance minister P Chidambaram and commerce minister Kamal Nath.

Related Posts:

Sunday, November 27, 2005

Management Improvement

Topic: Management Improvement

Lean Manufacturing Visionary Jim Womack On Frontiers Of Lean Thinking, webcast and additional questions and answers:

I believe while they are similar to varying degree they are not the same thing. They may have similar goals - they are largely focused at improving performance of the organization (but even how they would measure success is different). And when implemented well each of these methods have value. However what is done in an organization focused on six sigma is different than one focused on lean thinking.

These efforts can all be compatible. And while I believe differences do exist between these concepts, I largely agree:

Many of the tools are used between the different programs and many of the important concepts are similar. Some tools are much more common in one program, even if they are not limited to one program (such as Design of Experiments used heavily in six sigma). But design of experiments existed long before six sigma and was used by sensible people to improve for decades before six sigma.

The biggest difference I see in the programs is the overall aim. And that overall aim effects everything else. I happen to be a fan of Deming's ideas. Most of these programs take a great deal from Deming's ideas. I believe Lean is closest to Deming's ideas (which makes sense as Lean is essentially the Toyota Production System TPS). In 1991, Shoichiro Toyoda, Honorary Chairman and director of Toyota Motor Corporation stated:

At Toyota, Ohno and then Shingo created TPS, which includes many new ideas that are truly unique to TPS and are not really a part of what Deming taught, though they are consistent with his ideas. The focus of TPS is different than Deming's though much closer to Deming's ideas that most any other company. I believe they evolved to something that is unique and valuable. This is exactly what I would expect as more companies adopt better management methods and then proceed to evolve those methods in their organizations.

I think in the current application of lean thinking many ignore some of the valuable ideas from Deming (which may well be related to, as Womack stated: "packaging efforts of competing consultants"). Toyota obviously put a high value on Deming's ideas and those that try to adopt lean without understanding his ideas, can improve, but I believe they will be less successful over the long term.

Management concepts should evolve and improve over time. We should build upon the good ideas of yesterday and build in new innovations as they are shown to be effective. It is difficult to do so when consultants try to make their "solutions" proprietary methodologies that are sold in that way.

Luckily working with the ideas of Deming, Ohno, Drucker, achieve, Shingo, Scholtes, Womack, Box, etc.. and building upon them is what is needed to be successful. I find that management thinkers focused on improving management rather than selling a proprietary solution have the best ideas that are needed to improve management. Eli Goldratt and Joel Barker have some valuable ideas but seem to be more proprietary about those ideas, to me, than most of the others.

I will admit I am biased against proprietary solutions. I especially find it annoying as many proprietary solutions offer nothing actually unique, they just take old management tools and then rename them or twist a bit and claim this is some great new thing. I also think many hide their ideas from public scrutiny claiming they are "proprietary." I understand some good ideas are lurking in this area, still, I would be very reluctant to adopt proprietary management tools.

The continued evolving of quality management in six sigma, lean thinking and the adoption of many of the concepts into traditional management is a good thing. The current state of management improvement offers more good ideas and more refined ideas then ever before. And I do see lean thinking, six sigma, deming, systems thinking, theory of constraints, etc. as part of management improvement. The more learning from those focused in different areas there is the better; rather than forming isolated camps for improving the practice of management.

Related Posts:

Lean Manufacturing Visionary Jim Womack On Frontiers Of Lean Thinking, webcast and additional questions and answers:

Question: For a firm seeking to improve -- what comes first? Six Sigma quality or lean implementation?

James Womack: Agh! These are all the same thing. You need to start with the value stream for very product, draw a map of its current state, and ask about each step: Is it valuable? Is it capable? Is it available? Is it adequate? Is it flexible? Then ask whether each step flows smoothly to the next but only at the pull of the customer as the process approaches perfection. Doing this simple exercise wraps together everything you need to know about TQM, TPM, TPS, Six Sigma, TOC, etc

James Womack: Agh! These are all the same thing. You need to start with the value stream for very product, draw a map of its current state, and ask about each step: Is it valuable? Is it capable? Is it available? Is it adequate? Is it flexible? Then ask whether each step flows smoothly to the next but only at the pull of the customer as the process approaches perfection. Doing this simple exercise wraps together everything you need to know about TQM, TPM, TPS, Six Sigma, TOC, etc

I believe while they are similar to varying degree they are not the same thing. They may have similar goals - they are largely focused at improving performance of the organization (but even how they would measure success is different). And when implemented well each of these methods have value. However what is done in an organization focused on six sigma is different than one focused on lean thinking.

These efforts can all be compatible. And while I believe differences do exist between these concepts, I largely agree:

When I have a bit more time for a talk, I explain that "lean", "six sigma", and all the other programs focusing on process management are largely the same and are complimentary. It's only the packaging efforts of competing consultants that creates the perception of fundamentally different approaches.

Many of the tools are used between the different programs and many of the important concepts are similar. Some tools are much more common in one program, even if they are not limited to one program (such as Design of Experiments used heavily in six sigma). But design of experiments existed long before six sigma and was used by sensible people to improve for decades before six sigma.

The biggest difference I see in the programs is the overall aim. And that overall aim effects everything else. I happen to be a fan of Deming's ideas. Most of these programs take a great deal from Deming's ideas. I believe Lean is closest to Deming's ideas (which makes sense as Lean is essentially the Toyota Production System TPS). In 1991, Shoichiro Toyoda, Honorary Chairman and director of Toyota Motor Corporation stated:

"There is not a day I don't think about what Dr. Deming meant to us. Deming is the core of our management."

At Toyota, Ohno and then Shingo created TPS, which includes many new ideas that are truly unique to TPS and are not really a part of what Deming taught, though they are consistent with his ideas. The focus of TPS is different than Deming's though much closer to Deming's ideas that most any other company. I believe they evolved to something that is unique and valuable. This is exactly what I would expect as more companies adopt better management methods and then proceed to evolve those methods in their organizations.

I think in the current application of lean thinking many ignore some of the valuable ideas from Deming (which may well be related to, as Womack stated: "packaging efforts of competing consultants"). Toyota obviously put a high value on Deming's ideas and those that try to adopt lean without understanding his ideas, can improve, but I believe they will be less successful over the long term.

Management concepts should evolve and improve over time. We should build upon the good ideas of yesterday and build in new innovations as they are shown to be effective. It is difficult to do so when consultants try to make their "solutions" proprietary methodologies that are sold in that way.

Luckily working with the ideas of Deming, Ohno, Drucker, achieve, Shingo, Scholtes, Womack, Box, etc.. and building upon them is what is needed to be successful. I find that management thinkers focused on improving management rather than selling a proprietary solution have the best ideas that are needed to improve management. Eli Goldratt and Joel Barker have some valuable ideas but seem to be more proprietary about those ideas, to me, than most of the others.

I will admit I am biased against proprietary solutions. I especially find it annoying as many proprietary solutions offer nothing actually unique, they just take old management tools and then rename them or twist a bit and claim this is some great new thing. I also think many hide their ideas from public scrutiny claiming they are "proprietary." I understand some good ideas are lurking in this area, still, I would be very reluctant to adopt proprietary management tools.

The continued evolving of quality management in six sigma, lean thinking and the adoption of many of the concepts into traditional management is a good thing. The current state of management improvement offers more good ideas and more refined ideas then ever before. And I do see lean thinking, six sigma, deming, systems thinking, theory of constraints, etc. as part of management improvement. The more learning from those focused in different areas there is the better; rather than forming isolated camps for improving the practice of management.

Related Posts:

Friday, November 25, 2005

Google: Experiment Quickly and Often

Topic: Management Improvement

Google Thinks Small by Quentin Hardy, Forbes:

Google has advantages in making this work for them (it is easy to find reasons it won't work elsewhere). However, this is basically piloting changes on a small scale, analyzing the results and doing that quickly and often. That quick, frequent experimentation is something organizations should strive to achieve.

The clear visible mission is also helpful. When an organization has an organizing principle everyone can understand then action can be guided by individual aim toward that purpose. When the understanding is missing organizations often have to rely on top down instruction and having far too many issues passed up the hierarchy for a decision.

And getting a small group of people to make things work quickly is also great. Many organizations get bogged down with byzantine management structures that slow action to a crawl.

Google Thinks Small by Quentin Hardy, Forbes:

Brin and Page have created a corporate organism that tackles most big projects in small, tightly focused teams, setting them up in an instant and breaking them down weeks later without remorse. "Their view is that there is much greater progress if you have many small teams going out at once," Schmidt says. The mission overall: to collect "all the world's information" and make it accessible to everyone. "It's a cause."

...

Hundreds of projects go on at the same time. Most teams throw out new software in six weeks or less and look at how users respond hours later.

...

Hundreds of projects go on at the same time. Most teams throw out new software in six weeks or less and look at how users respond hours later.

Google has advantages in making this work for them (it is easy to find reasons it won't work elsewhere). However, this is basically piloting changes on a small scale, analyzing the results and doing that quickly and often. That quick, frequent experimentation is something organizations should strive to achieve.

The clear visible mission is also helpful. When an organization has an organizing principle everyone can understand then action can be guided by individual aim toward that purpose. When the understanding is missing organizations often have to rely on top down instruction and having far too many issues passed up the hierarchy for a decision.

And getting a small group of people to make things work quickly is also great. Many organizations get bogged down with byzantine management structures that slow action to a crawl.

Thursday, November 24, 2005

2005 Baldrige Award

The 2005 Baldrige Award recipients are:

- Sunny Fresh Foods, Inc., Monticello, Minn. (manufacturing)

- Product rejections for SFF at all four plants have continuously declined. Reducing rework can provide significant productivity improvements: SFF's rework reduction percentage was measured at 15 percent from 2001 to 2002, 61 percent from 2002 to 2003, and 75 percent from 2003 to 2004.

- DynMcDermott Petroleum Operations, New Orleans, La. (service)

- The storage cost per barrel was $3.00 for Japanese Oil Reserves, $2.40 for U.S. industry storage, $1.60 for the European Oil Stockpile and $.20 for the Strategic Petroleum Reserve, managed by DynMcDermott.

- Park Place Lexus, Plano, Texas (small business)

- Park Place Lexus Grapevine location had a New Car Client Satisfaction Index (CSI) of 99.8 percent in 2004 making it the highest rated Lexus dealership in the nation

- Richland College, Dallas, Texas (education)

- RLC's systematic process for design and evaluation of learning-centered processes utilizes a combination of qualitative, quantitative, in-process formative and end-process summative measures to ensure process requirements are met and to manage processes during day-to-day operations. In addition, standardized process drivers, such as measurements for its many KPIs, and defined curricula for learning processes help ensure a repeatable system is used to meet requirements.

- Jenks Public Schools, Jenks, Okla. (education)

- Drop-out rates, a measure of student satisfaction for JPS students, have decreased steadily from 6.3 percent in 1999 to 1.2 percent at the close of the 2004 school year.

- Bronson Methodist Hospital, Kalamazoo, Mich. (health care)

- BMH shows strong performance improvement and results in Medicare Mortality Rate (mortality rates of people over 65 enrolled in Medicare programs), moving from 4.8 percent in 2002 to 3.5 percent for January-July 2005. This performance exceeds both the CareScience Expected Standard, and the CareScience Best Practice.

Tuesday, November 22, 2005

Be Thankful for Lean Thinking

Topics: Management Improvement and Economics

Topics: Management Improvement and EconomicsThe Dallas Federal Reserve white paper, Supply Chain Management: The Science of Better, Faster, Cheaper by Thomas F. Siems provides a macroeconmic view of what to be thankful due to the practice of lean thinking:

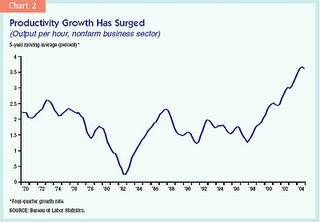

Through better information engineering, supply chain improvements have resulted in a reduced bullwhip effect, lower inventory levels, reduced logistics costs, and streamlined payments. These improvements appear to have helped produce macroeconomic benefits such as more stable economic output and higher productivity growth.

Mass Production Era. In the early 1900s, Henry Ford created the first moving assembly line. This reduced the time required to build a Model T from 728 hours to 1.5 hours and ushered in the mass production era. Over the next 60 years, American manufacturers became adept at mass production and streamlined supply chains with the help of scientific management methods and operations research techniques.

Lean Manufacturing Era. But in the 1970s, U.S. manufacturing's superiority was challenged. Foreign firms in many industries made higher quality products at lower costs. Global competition forced U.S. manufacturers to concentrate on improving quality by reducing defects in their supply chains.

Starting in the early 1970s, Japanese manufacturers like Toyota changed the rules of production from mass to lean. Lean manufacturing focuses on flexibility and quality more than on efficiency and quantity. Significant lean manufacturing ideas include six-sigma quality control, just-in-time inventory and total quality management.

Lean Manufacturing Era. But in the 1970s, U.S. manufacturing's superiority was challenged. Foreign firms in many industries made higher quality products at lower costs. Global competition forced U.S. manufacturers to concentrate on improving quality by reducing defects in their supply chains.

Starting in the early 1970s, Japanese manufacturers like Toyota changed the rules of production from mass to lean. Lean manufacturing focuses on flexibility and quality more than on efficiency and quantity. Significant lean manufacturing ideas include six-sigma quality control, just-in-time inventory and total quality management.

Ok, I don't think most experts would call six-sigma a lean manufacturing idea but this is a member of the dismal science singing macro-economic praises for the practice of lean thinking, so I think that point can be overlooked.

Sunday, November 20, 2005

Innovation and Research and Development

Topic: Economics and Management Improvement

Innovation and R&D by John Hagel:

I would argue innovation can be related to productivity improvement or it can be completely unrelated. A company could innovate with an ideas like the remote control for televisions (or microlending or air bags). That innovation may not contribute in any way to manufacturing televisions more productively.

Other innovation may be related to improving the productivity alone and add no additional functionality to the customer. Many innovations will provide a combination of both benefits. Both innovation and productivity improvement are important.

Quoting Michael Schrage's article:

John Hagel then states:

I agree with the weakness of using research spending and patents to measure innovation. I do not believe they are worthless as measures, however. Are there better measures? Outcome measures? If so, what are they? From the post I might guess productivity improvement might be such a measure. While that might be a useful measure it is hardly a sufficient one. I agree people should understand the weaknesses with the measures but I still believe they are useful in understanding where things stand and how things are changing.

The Innovation/Productivity Quotient by John Hagel III and John Seely Brown:

Related posts:

Innovation and R&D by John Hagel:

From a competitive viewpoint, what matters is the relative rate of productivity improvement. R&D spending and patent filings will matter little if they do not translate into faster productivity improvement -– in fact, they can be a significant distraction. Those who understand this will have a significant edge as competition intensifies in the global economy.

I would argue innovation can be related to productivity improvement or it can be completely unrelated. A company could innovate with an ideas like the remote control for televisions (or microlending or air bags). That innovation may not contribute in any way to manufacturing televisions more productively.

Other innovation may be related to improving the productivity alone and add no additional functionality to the customer. Many innovations will provide a combination of both benefits. Both innovation and productivity improvement are important.

Quoting Michael Schrage's article:

The simple fact is that R&D spending - whether in euros, dollars or as a percentage of sales - is an input, not a measure of efficiency, effectiveness or productivity. Ingenuity, invention and innovation are rarely functions of budgetary investment.

John Hagel then states:

I only wish that Michael had gone a bit further and spent more time attacking a related fallacy: equating patents with innovation.

I agree with the weakness of using research spending and patents to measure innovation. I do not believe they are worthless as measures, however. Are there better measures? Outcome measures? If so, what are they? From the post I might guess productivity improvement might be such a measure. While that might be a useful measure it is hardly a sufficient one. I agree people should understand the weaknesses with the measures but I still believe they are useful in understanding where things stand and how things are changing.

The Innovation/Productivity Quotient by John Hagel III and John Seely Brown:

The real winners in terms of IT investment to generate major productivity advances have been highly innovative at two levels: They redesigned key business processes to exploit IT capabilities, and they focused on implementing continuing innovations in these business processes.

Related posts:

Saturday, November 19, 2005

Laurence Haughton on Peter Drucker

Laurence Haughton on Peter Drucker via ChristianSarkar.com:

It is frustrating, but I wouldn't draw that conclusion.

As readers of this blog know, I am a big fan of W. Edwards Deming's ideas. Many of his ideas are ignored. However, even so, his influence on management in America, and worldwide, has been significant and positive. The way I see it even though managers are only benefiting from say 20% of the wisdom of Deming or Drucker that could very well still make Deming or Drucker the most influential management expert.

updated: Also see the Slacker Manager post on The Drucker paradox

He criticized organizations who issued directives to "cut 5 or 10 percent from budgets across the board."

...

And I'll bet others can find 100 additional quoted and ignored lessons from Peter Drucker just like that one

...

I'm sorry to say that despite all the tributes, up to now, we've learned very little from Peter Drucker.

...

And I'll bet others can find 100 additional quoted and ignored lessons from Peter Drucker just like that one

...

I'm sorry to say that despite all the tributes, up to now, we've learned very little from Peter Drucker.

It is frustrating, but I wouldn't draw that conclusion.

As readers of this blog know, I am a big fan of W. Edwards Deming's ideas. Many of his ideas are ignored. However, even so, his influence on management in America, and worldwide, has been significant and positive. The way I see it even though managers are only benefiting from say 20% of the wisdom of Deming or Drucker that could very well still make Deming or Drucker the most influential management expert.

updated: Also see the Slacker Manager post on The Drucker paradox

Management Science for Software Engineering

Topics: Management Improvement, Software Development, Theory of Constraints

Management Science for Software Engineering:

Read the full paper by David Anderson, Microsoft, From Worst to Best in 9 Months - Implementing Drum-Buffer-Rope in Microsoft's IT Department:

An excellent article for those interested in project management and software development (as well as those interested in Theory of Constraints, of course). David Anderson continues to post excellent material detailing actual results.

Related Posts:

Management Science for Software Engineering:

using the Theory of Constraints 5 focusing steps and the drum-buffer-rope solution for production flow problems, it was possible to increase the productivity of a sustained engineering department by more than 200%. In the final, quarter of the study period, a 25% increase (elevation) of the capacity constrained resource, produces a 25% increase in overall system throughput - just as the theory and model would predict.

Read the full paper by David Anderson, Microsoft, From Worst to Best in 9 Months - Implementing Drum-Buffer-Rope in Microsoft's IT Department:

Estimation was sucking up to 40% of capacity. Removing estimating produced a big and immediate productivity improvement [Table 3]. However, permission to stop estimating required a change in mindset from customers and internal management. They needed to stop the cost accounting for prioritization and budgeting.

An excellent article for those interested in project management and software development (as well as those interested in Theory of Constraints, of course). David Anderson continues to post excellent material detailing actual results.

Related Posts:

Wednesday, November 16, 2005

Managing Innovation

TQM, ISO 9000, Six Sigma: Do Process Management Programs Discourage Innovation?

Well I don't think the idea that innovation is needed was not understood decades ago. It seems to be one of the typical refrains when people want to change - oh that old stuff was only about x and now we need to focus on Y.

I commented on this before: Fast Company Interview: Jeff Immelt

As to focusing only on measurable items: yeah that has been recognized as bad, again for decades.

I disagree. Managing processes is a good idea. You manage appropriately to the process, of course.

Google has a very well known management commitment to allowing engineering one day a week to work on personal projects:

You manage processes such as thinking up a new way to use computer technology than you a process to manufacture tires. But the idea that you don't manage and improve the process just because the process seems discontinuous is a mistake.

Some thoughts on managing innovation:

"In the appropriate setting, process management activities can help companies improve efficiency, but the risk is that you misapply these programs, in particular in areas where people are supposed to be innovative," notes Benner. "Brand new technologies to produce products that don't exist are difficult to measure. This kind of innovation may be crowded out when you focus too much on processes you can measure."

Well I don't think the idea that innovation is needed was not understood decades ago. It seems to be one of the typical refrains when people want to change - oh that old stuff was only about x and now we need to focus on Y.

I commented on this before: Fast Company Interview: Jeff Immelt

As to focusing only on measurable items: yeah that has been recognized as bad, again for decades.

Says Benner: "Our message is this: Companies that have process management in one area must realize that it can bleed into other areas of the company, and you must prevent that from happening. Use these approaches where they make sense -- and deliberately do not have them in areas that are focused on innovation."

I disagree. Managing processes is a good idea. You manage appropriately to the process, of course.

Google has a very well known management commitment to allowing engineering one day a week to work on personal projects:

Google engineers all have '20 percent time' in which they're free to pursue projects they're passionate about. This freedom has already produced Google News, Google Suggest, AdSense for Content, and Orkut - products which might otherwise have taken an entire start-up to launch.

You manage processes such as thinking up a new way to use computer technology than you a process to manufacture tires. But the idea that you don't manage and improve the process just because the process seems discontinuous is a mistake.

Some thoughts on managing innovation:

- Deming on Innovation

- Gary Hamel articles

- Edward deBono

- Fast Cycle Change in Knowledge-Based Organizations by Ian Hau and Ford Calhoun

- Clayton Christensen: official site - aricles via curious cat search

Tuesday, November 15, 2005

Curious Cat Science and Engineering blog

Topic: Science and Engineering

We have moved the Curious Cat Science and Engineering blog to a new home.

About Our Science and Engineering Blog:

The title of the blog gives you an idea of the topics we explore. Some additional insight into our aim:

We have moved the Curious Cat Science and Engineering blog to a new home.

About Our Science and Engineering Blog:

The title of the blog gives you an idea of the topics we explore. Some additional insight into our aim:

- Primary education (k-12) in science, math and engineering - we will post about the state of education (research etc.) and news and items of interest to teachers and students. We aim to be a resource that helps teachers and students learn about science and engineering. The K-12 category will be targeted at teachers and students. We are also trying a students category for items we think might be of particular interest to students (and we believe teachers might find useful as items to interest students in science and engineering).

- Higher education (college, university, graduate school and other sources of advanced learning) - we will post about news about science and engineering higher education and items of interest to professor, students and those interested in higher education. The higher education category will be targeted at professors, students and those interested in higher education.

- Economic impact of science and engineering - we will post about the macro economic and societal impacts of science and engineering: higher education, research funding, investments and political decisions and discussions. We believe science, engineering and technology can serve to improve living conditions around the world. We believe investments in science and engineering, research and higher education, will impact the economic success of countries and the world overall. The economics category contains posts on developments in this are and our thoughts on this topic.

- Highlight interesting science and engineering information - we will post about interesting science and engineering news and blog posts as we see it.

Saturday, November 12, 2005

Management Guru Peter Drucker 1909-2005

Management expert Peter Drucker passed away at age 95. Peter F. Drucker Information from Claremount University.

Management expert Peter Drucker passed away at age 95. Peter F. Drucker Information from Claremount University.In 2002, Peter Ferdinand Drucker was awarded the United States Presidential Medal of Freedom.

Drucker, was born in Vienna, Austria, in 1909 and moved to the United States in 1937. He taught at New York University as Professor of Management from 1950 to 1971. From 1971 through 2002 he taught at Claremont University. The university's School of Management was named for him in 1987.

He has written influential works about management since the 1940s. He has written about 30 books, and from 1975 to 1995 he was an editorial columnist for the Wall Street Journal.

He consulted for businesses and non-profit organizations. In 1990 he founded what is now the Leader to Leader Foundation. Curious Cat Peter Drucker Biography.

Management Visionary Peter Drucker Dies by Patricia Sullivan:

"There is only one valid definition of business purpose: to create a customer," he said 45 years ago. Central to his philosophy was the belief that highly skilled people are an organization's most valuable resource and that a manager's job is to prepare and free people to perform. Good management can bring economic progress and social harmony, he said

...

Mr. Drucker demanded that public and private organizations operate ethically and decried managers who reap bonuses by laying off employees. "This is morally and socially unforgivable, and we will pay a heavy price for it," he said.

...

Mr. Drucker demanded that public and private organizations operate ethically and decried managers who reap bonuses by laying off employees. "This is morally and socially unforgivable, and we will pay a heavy price for it," he said.

Addition: My Grandfather, Peter Drucker, Died Today

Update 2: Management Guru Peter Drucker - podcast interview, on NPR, with Peter Drucker on management, the state of the world today and where we are headed. A profound view from Peter Drucker in his 95th year.

News articles: washingtonpost.com - CNN - LA Times

Wednesday, November 09, 2005

Government Lean Six Sigma

Topic: Management Improvement

Deep Thinkers by Kimberly Palmer, GovExec.com:

Unfortunately I would have to say the article does strike me as talking about fadish behavior ,not true transformation in management approaches. I was involved in management improvement efforts in government for years and the government does have examples of very well managed organizations (as well as poorly managed organizations). And too often superficial improvements were seen as a significant achievement. The article talks about things that are fine but just touch the surface of the needed improvements.

One of the problems in government management improvement is the mobility of management. To an even higher degree than Deming noted as a "deadly disease" of American business excessive mobility of management in government makes significant long term management improvement difficult. Exceptional managers often move up or move out long before the changes they start take a firm hold.

When looking at lean initiatives in government I think it is sensible to separate political from operational efforts. Ideally the political decisions should be informed by knowledgeable management experts. However, focusing on that is a recipe to frustration as political decisions will often remain mostly political (which have as factors how efficient and how effective a solution may be, but those are only factors and rarely the primary factor).

However, much of what government does is carry out the political decisions that are largely settled. And within those areas a framework eliminating waste is a great goal (as is effective solutions - elimination of waste is necessary but not sufficient). The decision on how the saving from elimination of waste should be used is again a political question.

Once the political decision has been made to eradicate polio then that desire can be carried out - and politics really has little impact. Other examples are not as simple. A political decision to eliminate AIDS runs into political controversies in selecting the best strategies to accomplish the goal.

A desire to eliminate hunger, poverty or homelessness run into differing opinions on how those problems should be addressed. I can't imagine any politician against the elimination of those problems. However, many politicians will be against various tactics to accomplish those goals.

Political decisions have management components but arguing about the poor management effectiveness of political decisions is a bit too advanced for our current capability, I believe. It seems silly for a government to subsidize mansions being built in hazardous areas where insurers would not insure construction, but for political reasons it continues. It seems silly to have the political leadership prohibit the government from negotiating lower drug costs from suppliers (Drug Dealings - Working to fix the problems with the new Medicare law), but they do.

Why would a government provide special tax breaks to big oil companies (Corporate Tax Bill, HR 4520 - House OKs energy bill laden with tax breaks) and they a few months later hold hearings on imposing special taxes on big oil companies "windfall" profits (Oil industry under fire - Oil Doesn't Want Focus on Big Profit). These political decisions, are worthy of both political and managerial criticism.

If aiming for management improvement in government there are huge targets of opportunities that will not run into political controversy. These areas of opportunity for extensive management improvement are the most sensible place to focus on government management improvement (almost nothing is free from politics but some things are less subject to those whims than others).

Focusing on more sensible systems thinking in political decisions is also fine but I think the focus there should be political. The focus should be on finding politically venerable decisions and pointing out the ineffectiveness of spending resources in such a manner.

If you want to see some examples of effective government look at the rates government pays for plane travel. When government agencies are freed to do their jobs they often do well - they also fail to do well. The scope of government is huge and includes examples of great and poor management.

How much credit does the United States government get for creating the conditions that allowed for Yahoo, Google, Ebay, Amazon... to grow? How much credit does it get for assisting in the sequencing the human genome? How much credit for creating a interstate highway system that allows for efficient transportation system? How much credit for create a society with the rule of law? How much credit for rebuilding the spirit of New York City? How much credit for creating and enforcing the American with Disabilities Act? How much credit for funding a child welfare system and giving a child a chance to flourish and become a productive member of society? How much credit for taking criminals off the street? How much credit for regulators taking action to provide clean water and air? How much credit for providing health care to those who do not have insurance or a way to pay? How much credit for educating a child? How much credit does the Japanese or Singaporian governments get for the economic growth the citizens have enjoyed? Most of these figures are unknown and unknowable?

Federal, state and local government needs to improve their management practices (as do other portions of our society). However, government also does well.

Some examples of effective government management:

Deep Thinkers by Kimberly Palmer, GovExec.com:

"This is not a fad that will die out. It's been tried, it's been tested, it's true. If you look at the best-run companies in industry, this is part of the heart and soul that's making them successful," says Mark Price, president of George Group Federal Services, part of Dallas-based George Group Consulting.

Unfortunately I would have to say the article does strike me as talking about fadish behavior ,not true transformation in management approaches. I was involved in management improvement efforts in government for years and the government does have examples of very well managed organizations (as well as poorly managed organizations). And too often superficial improvements were seen as a significant achievement. The article talks about things that are fine but just touch the surface of the needed improvements.

One of the problems in government management improvement is the mobility of management. To an even higher degree than Deming noted as a "deadly disease" of American business excessive mobility of management in government makes significant long term management improvement difficult. Exceptional managers often move up or move out long before the changes they start take a firm hold.

When looking at lean initiatives in government I think it is sensible to separate political from operational efforts. Ideally the political decisions should be informed by knowledgeable management experts. However, focusing on that is a recipe to frustration as political decisions will often remain mostly political (which have as factors how efficient and how effective a solution may be, but those are only factors and rarely the primary factor).

However, much of what government does is carry out the political decisions that are largely settled. And within those areas a framework eliminating waste is a great goal (as is effective solutions - elimination of waste is necessary but not sufficient). The decision on how the saving from elimination of waste should be used is again a political question.

Once the political decision has been made to eradicate polio then that desire can be carried out - and politics really has little impact. Other examples are not as simple. A political decision to eliminate AIDS runs into political controversies in selecting the best strategies to accomplish the goal.

A desire to eliminate hunger, poverty or homelessness run into differing opinions on how those problems should be addressed. I can't imagine any politician against the elimination of those problems. However, many politicians will be against various tactics to accomplish those goals.

Political decisions have management components but arguing about the poor management effectiveness of political decisions is a bit too advanced for our current capability, I believe. It seems silly for a government to subsidize mansions being built in hazardous areas where insurers would not insure construction, but for political reasons it continues. It seems silly to have the political leadership prohibit the government from negotiating lower drug costs from suppliers (Drug Dealings - Working to fix the problems with the new Medicare law), but they do.

Why would a government provide special tax breaks to big oil companies (Corporate Tax Bill, HR 4520 - House OKs energy bill laden with tax breaks) and they a few months later hold hearings on imposing special taxes on big oil companies "windfall" profits (Oil industry under fire - Oil Doesn't Want Focus on Big Profit). These political decisions, are worthy of both political and managerial criticism.

If aiming for management improvement in government there are huge targets of opportunities that will not run into political controversy. These areas of opportunity for extensive management improvement are the most sensible place to focus on government management improvement (almost nothing is free from politics but some things are less subject to those whims than others).

Focusing on more sensible systems thinking in political decisions is also fine but I think the focus there should be political. The focus should be on finding politically venerable decisions and pointing out the ineffectiveness of spending resources in such a manner.

If you want to see some examples of effective government look at the rates government pays for plane travel. When government agencies are freed to do their jobs they often do well - they also fail to do well. The scope of government is huge and includes examples of great and poor management.

How much credit does the United States government get for creating the conditions that allowed for Yahoo, Google, Ebay, Amazon... to grow? How much credit does it get for assisting in the sequencing the human genome? How much credit for creating a interstate highway system that allows for efficient transportation system? How much credit for create a society with the rule of law? How much credit for rebuilding the spirit of New York City? How much credit for creating and enforcing the American with Disabilities Act? How much credit for funding a child welfare system and giving a child a chance to flourish and become a productive member of society? How much credit for taking criminals off the street? How much credit for regulators taking action to provide clean water and air? How much credit for providing health care to those who do not have insurance or a way to pay? How much credit for educating a child? How much credit does the Japanese or Singaporian governments get for the economic growth the citizens have enjoyed? Most of these figures are unknown and unknowable?

Federal, state and local government needs to improve their management practices (as do other portions of our society). However, government also does well.

Some examples of effective government management:

- Transformation and Redesign at the White House Communications Agency by March Laree Jacques

- Doing More with Less in the Public Sector: a Progress Report from Madison, Wisconsin William Hunter, Jan O'Neill and Carol Wallen

- Quality Improvement and Government: Ten Hard Lessons From the Madison Experience

- Innovations in American Government

Friday, November 04, 2005

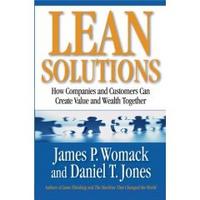

Interview with Jim Womack

Topic: Management Improvement

Topic: Management ImprovementQ&A With Jim Womack by Mark Graban:

The whole idea of lean solutions is to start with today's customer in today's circumstances and ask what the customer really wants. When we do this, the first thing to note is that manufactured goods have gotten vastly better, somewhat cheaper

James Womack also lists the six principles of Lean Solutions which seems to be boil down to one of the principles: "Get me exactly what I want" (though the way he describes this seems to be different than I read those words - "The proposition of retailers and other providers of goods from stock is that you can always find any of the items they have on offer"). That concept in then clarified by explaining what people want, such as: "don't waste my time," "Solve my problem completely," give it to me when and where I want...

We believe that by looking at the process the consumer follows to solve problems, comparing this with the process the provider follows (along with the manufacturer), and then synchronizing and rationalizing all three processes, we can product a win-win-win for consumers, providers, and manufacturers. These win-win-wins are lean solutions.

But we have also noticed for years the growing gap between the factory, where things are getting better, and the situation of providers and consumers where it often appears that things are getting worse.

...

We strongly believe that our future standard of living in America, Europe and Japan largely depends on our ability to improve the consumption and provision processes.

...

We strongly believe that our future standard of living in America, Europe and Japan largely depends on our ability to improve the consumption and provision processes.

I agree. It is frustrating to see the poor results in improving performance in service industries. One of the reasons manufacturing has been so beneficial to economies is that manufacturing productivity has been increasing dramatically.

Productivity increases provide economic gains that then can be distributed to the members of the economy. As other segments grow as a portion of the economy the manufacturing productivity gains do not carry the same weight as they did when manufacturing made up a larger percentage of the economy. Achieving such productivity gains in other parts of the economy is a key to economic success.

Articles by James Womack

Wednesday, November 02, 2005

Lean Information Technology

Topic: Management Improvement

A new Lean Blog, Compound Thinking, focuses on Information Technology. It has started off with some interesting posts, including - Compound Thinking: Lean Manufacturing Principles -- Trust the Team:

And Lean Manufacturing Practices -- Kaizan:

I agree. It is very easy for waste to be hidden in IT. I think it is more difficult to notice the inefficiencies in IT because much of the work is done in virtual space, not real space. I think that can make it more difficult to see the waste. Or perhaps I am just using that as an excuse.

I agree. It is very easy for waste to be hidden in IT. I think it is more difficult to notice the inefficiencies in IT because much of the work is done in virtual space, not real space. I think that can make it more difficult to see the waste. Or perhaps I am just using that as an excuse.

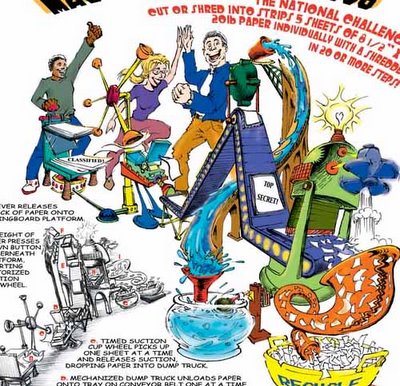

IT people also can hack something to meet today's need and add it to the code base. It would normally be much more difficult to modify production machines. While this is an advantage (more flexibility) it often leads to sloppy systems. Instead of taking the time to design these properly something is created quickly, for today. If the code had a physical existence I think much of it would look like a rube Goldberg contraption.

Image from Rube Goldberg contest site

A new Lean Blog, Compound Thinking, focuses on Information Technology. It has started off with some interesting posts, including - Compound Thinking: Lean Manufacturing Principles -- Trust the Team:

If you aren't trusting your people, you are slowly but surely sapping their morale. Even worse, you are cutting yourself from the source of real ground-floor process innovation.

And Lean Manufacturing Practices -- Kaizan:

IT Departments need Kaizan events, new technology is coming at them faster than they can manage, processes aren't automated just because nobody has a free couple of hours, and things can get messy very quickly.

I agree. It is very easy for waste to be hidden in IT. I think it is more difficult to notice the inefficiencies in IT because much of the work is done in virtual space, not real space. I think that can make it more difficult to see the waste. Or perhaps I am just using that as an excuse.

I agree. It is very easy for waste to be hidden in IT. I think it is more difficult to notice the inefficiencies in IT because much of the work is done in virtual space, not real space. I think that can make it more difficult to see the waste. Or perhaps I am just using that as an excuse.IT people also can hack something to meet today's need and add it to the code base. It would normally be much more difficult to modify production machines. While this is an advantage (more flexibility) it often leads to sloppy systems. Instead of taking the time to design these properly something is created quickly, for today. If the code had a physical existence I think much of it would look like a rube Goldberg contraption.

Image from Rube Goldberg contest site

Subscribe to:

Posts (Atom)